Shipping containers are the backbone of efficient logistics when it comes to global trade. From everyday consumer goods to specialized cargo, these containers make it possible to move products safely, reliably, and cost-effectively across the world. But not all containers are created equal. Choosing the right one can be the difference between streamlined operations and costly setbacks. This article breaks down seven of the most common shipping container types, highlighting their features and how they can strengthen your supply chain.

The Importance of Choosing the Right Container

Understanding container types is vital for your supply chain. The right choice can streamline operations, cut costs, and protect goods, while the wrong one may cause delays, damage, or added expenses. Matching the container to the cargo’s needs is key to a robust supply chain.

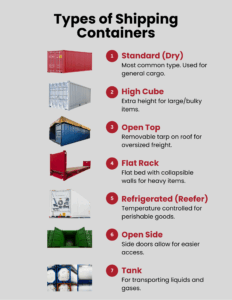

Types of Shipping Containers

Standard (Dry) Container

The Standard (Dry) container, typically 20 or 40 feet long, is the most common type, ideal for general cargo like electronics and textiles. Its enclosed, ribbed design shields goods from the elements. Widely compatible with ships, trucks, and trains, it simplifies intermodal logistics, making it a cost-effective staple for most shipments.

High Cube Container

The High Cube container, at 9.5 feet tall versus the standard 8.5 feet, provides extra height for bulky items like machinery or stacked pallets. This added space optimizes cargo consolidation, reducing the number of containers needed. It’s a favorite in industries like furniture and automotive, enhancing volume efficiency.

Open Top Container

With a removable tarpaulin roof, the Open Top container is perfect for oversized cargo, such as industrial equipment or tall structures. Cranes can load items from above, and the tarpaulin then secures them against weather. This flexibility speeds up handling and accommodates cargo needing specific orientation.

Flat Rack Container

The Flat Rack container features a flat bed with collapsible end walls, designed for heavy or oversized loads like vehicles and construction materials. Its open design allows loading from the sides or top, and the lack of side walls suits wide cargo, offering versatility and secure transport for unconventional items.

Refrigerated (Reefer) Container

The Refrigerated (Reefer) container, with a cooling unit, maintains temperatures from -25°C to +25°C, essential for perishables like food or pharmaceuticals. Its insulation and real-time monitoring ensure quality and compliance with regulations, making it indispensable for preserving sensitive goods across long distances.

Open Side Container

Featuring side doors, the Open Side container offers easy cargo access, ideal for items like long pipes or large crates that are tricky to load through end doors. This design cuts handling time and costs, and it doubles as accessible storage, boosting warehouse efficiency.

Tank Container

The Tank container, a cylindrical tank within a frame, is built for liquids and gases like chemicals or food-grade oils. Its robust, leak-proof design meets strict safety standards, ensuring secure transport of hazardous or sensitive substances, critical for specialized supply chains.

Understanding the various types of shipping containers is crucial for optimizing your supply chain and ensuring the safe, efficient, and cost-effective transport of goods. Whether you’re dealing with standard dry containers, high cube containers, open top containers, flat racks, refrigerated units, open side containers, or tank containers, selecting the right type tailored to your cargo’s needs can significantly enhance operational efficiency and reduce potential setbacks.

At Native American Logistics, we specialize in providing comprehensive logistics solutions that align with your specific shipping requirements. Our expertise in container selection and freight management ensures that your goods are transported securely and efficiently, regardless of their size, weight, or nature.

Ready to streamline your logistics operations? Contact us today to discuss how our tailored shipping solutions can meet your unique needs and drive your business forward.

Jeff Berlin

is the Chief Operating Officer of E.L. Hollingsworth & Co. and serves as the Senior Operations Executive for TOP Worldwide and Native American Logistics. With over 30 years of experience leading logistics and trucking companies, he brings deep industry expertise to his role. Jeff is also a CDL-A driver and a private pilot. Contact Jeff at jberlin@elhc.net.

+1 877 781 3006

+1 877 781 3006 (52) 554-870-5682

(52) 554-870-5682