Efficiency is everything when you’re running a supply chain, and businesses are constantly looking for smarter ways to move goods. One strategy that’s gaining traction is MILK RUN LOGISTICS. At Native American Logistics, we help companies streamline their operations, reduce waste, and improve visibility using milk run strategies that keep supply chains running smoothly.

What Is a Milk Run?

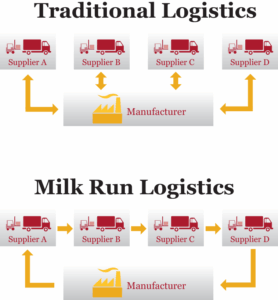

A milk run is a transportation route designed to pick up or deliver shipments from multiple suppliers or customers in a single trip. Think of it like the old-fashioned milk delivery route, but for modern manufacturing and distribution.

Instead of sending separate trucks for each shipment, a milk run consolidates them into one optimized route. This approach is perfect for businesses that handle frequent small shipments, multi-plant operations, or high-volume production.

Why Milk Run Logistics Matters

Businesses face pressure to cut costs, maintain speed, and keep supply chains reliable. Milk run logistics helps achieve these goals by:

Cutting Transportation Costs

Consolidating multiple pickups or deliveries into one trip reduces fuel use, driver hours, and empty miles. That means lower transportation costs and more efficient use of equipment.

Improving Inventory Control

Predictable delivery schedules help companies maintain just-in-time (JIT) inventory levels. Less excess stock means lower storage costs and less risk of obsolete materials.

Supporting Lean Manufacturing

Milk runs support lean operations by providing a consistent flow of materials without overstocking, keeping production running efficiently.

Boosting Supplier Performance

Structured pickup schedules make it easier for suppliers to plan, increasing accountability and reliability across the supply chain.

Enhancing Visibility

With modern tracking tools, milk run logistics offers real-time insights into shipments, helping companies proactively manage deliveries and production schedules.

How Milk Run Logistics Works

Implementing a milk run involves optimizing routes, scheduling pickups, and coordinating with suppliers. Key elements include:

-

Route Optimization – Planning the most efficient path for all pickups and deliveries.

-

Right-Sized Equipment – Using the proper truck or trailer for the shipment volume.

-

Scheduling & Frequency – Determining how often pickups and deliveries occur.

-

Technology Integration – Leveraging track-and-trace systems for full visibility.

-

Supplier Collaboration – Ensuring materials are ready when trucks arrive.

Who Benefits from Milk Runs

Milk runs are ideal for:

-

Multi-plant manufacturers

-

Companies with frequent small shipments

-

Businesses using lean or just-in-time strategies

-

Cross-border shippers needing reliable logistics

-

Organizations looking to cut costs and improve freight management

Combining Milk Runs with Premium Transportation

At Native American Logistics, we combine milk run planning with premium transportation to support high-value and time-sensitive shipments. This ensures:

-

Reliable delivery schedules

-

Seamless cross-border logistics

-

Optimized freight management

-

Faster response to supply chain disruptions

Partner with Native American Logistics

A well-designed milk run can reduce costs, improve efficiency, and strengthen your supply chain. At Native American Logistics, we tailor milk run programs to your operation, providing:

-

Custom route engineering

-

Real-time visibility and reporting

-

KPI-driven performance management

-

Scalable supply chain solutions

-

Proactive communication and problem-solving

Take the First Step

Streamline your supply chain and boost efficiency with a milk run solution designed for your business. Contact Native American Logistics today to explore how milk runs can transform your operations.

Jeff Berlin

is the Chief Operating Officer of E.L. Hollingsworth & Co. and serves as the Senior Operations Executive for TOP Worldwide and Native American Logistics. With over 30 years of experience leading logistics and trucking companies, he brings deep industry expertise to his role. Jeff is also a CDL-A driver and a private pilot.

Have a question about freight? Call or text Jeff directly at (810) 656-6343 or jberlin@elhc.net.

+1 877 781 3006

+1 877 781 3006 (52) 554-870-5682

(52) 554-870-5682